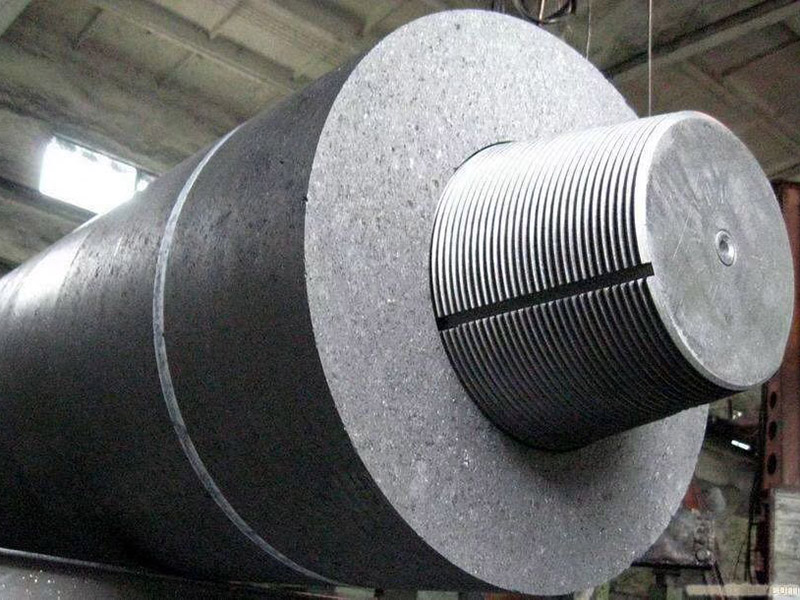

2022 China New Design Soldering Graphite Electrode - UHP Grades Graphite Electrodes – Sungraf Detail:

Products Details

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage

-

01

An increasing proportion of global steel is made using electric arc furnaces -

02

The electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Typical properties of UHP graphite electrodes

|

Applicable Furmace Dia |

AC Furnace |

DC Furnace |

|||

|

300-400mm |

450-500mm |

550-600mm |

650-700mm |

||

|

Bulk Density |

g/cm³ |

1.65~1.76 |

1.64~1.75 |

1.64~1.75 |

1.64~1.75 |

|

Specific Resistance |

μΩM |

4.2~6.0 |

4.2~6.0 |

4.2~6.0 |

4.2~5.5 |

|

Elastic Modulus |

Gpa |

7~14 |

7~14 |

7~14 |

7~14 |

|

kgf/mm² |

700~1,400 |

700~1,400 |

700~1,400 |

700~1,400 |

|

|

Flexural Strength |

MPa |

10.5~15 |

10~15 |

10~15 |

10~15 |

|

kgf/cm² |

105~150 |

100〜150 |

100-150 |

100~150 |

|

|

N/cm² |

1,050~1,500 |

1,000~1,500 |

1,000~1,500 |

1,000~1,500 |

|

|

Coefficient Of Thermal |

X10~-6/℃ |

1.0~1.5 |

1.0~1.5 |

1.0~1.5 |

1.0~1.4 |

|

Real Density |

g/cm³ |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

|

Porosity |

% |

20~26 |

20~27 |

20~27 |

20~27 |

|

Ash Content |

% |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

Typical properties of nipples

| Specifications |

≤φ400 |

φ450-500 |

φ550 |

φ600-700 |

| Specific Resistance (μΩM ) |

≤4.0 |

≤3.8 |

≤3.6 |

≤3.6 |

| Flexural Strength (MPa) |

18-24 |

17-25 |

20-28 |

20-28 |

| astic Modulus (GPa) |

≤18 |

≤18 |

≤18 |

≤18 |

| Bulk Density (g/cm³) |

1.76-1.84 |

1.78-1.84 |

1.79-1.86 |

1.79-1.86 |

| Coefficient Of Thermal Expansion (106/℃) |

0.9-1.3 |

0.9-1.2 |

0.9-1.1 |

0.9-1.1 |

| Ash Content (%) |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Current carrying capacity for UHP graphite electrodes

| Current Capacity Of UHP Graphite Electrodes | |||||

| Specifications | Current Capacity(A) | Current Density(A/cm²) | |||

| (inch) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our great provider and item for 2022 China New Design Soldering Graphite Electrode - UHP Grades Graphite Electrodes – Sungraf , The product will supply to all over the world, such as: Istanbul, Rome, Mali, Our company has already had a lot of excellent factories and professional technology teams in China, offering high quality products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

The customer service staff's answer is very meticulous, important is that the product quality is very good, and packaged carefully, shipped quickly!