High Quality Synthetic Graphite Powder - Bulletin Graphite Resillient Graphite – Sungraf Detail:

Products Details

Graphite is a coarse-sized plugging agent used in water, oil or synthetic-based drilling fluids to bridge and seal permeable and fractured formations. When drilling depleted zones exposed to high different pressures, the bridging and plugging capabilities of GRAPHITE additive can reduce the potential for stuck pipe. Graphite is chemically inert and thermally stable, and will not affect rheological properties when used at recommended concentrations. It can lower the potential for lost circulation and reduce torque and drag in many drilling applications.

Typical Physical Properties

Physical appearance:Black powder

Specific gravity: 2.19-2.26

Application

Graphite additive is designed to be used in any type of drilling fluid to bridge and seal permeable fractured formations, thus controlling lost circulation and reducing the possibility of differential sticking. Graphite can also be used to decreases the coefficient of friction (CoF) of drilling fluids. The recommended treatment for seepage losses (<10 bbl/hr or 1.6 m3/hr) is 15 to 20lb/bbl (43 to 57 kg/m3) in spotted pills or sweeps. The recommended treatment for partial losses (10 to 100 bbl/h or 1.6 to 16 m3/hr) is 20 to 50 lb/bbl (57 to 143 kg/m3) in spotted pills.

Graphite may require additional wetting agent when used in an oil-or synthetic-based mud system.

Advantages

• Effective bridging and sealing agent for a wide range of formations severity of losses.

• Controls seepage losses, thereby reducing the possibility of differential sticking.

• Decreases the CoF to reduce torque and drag in all mud systems.

• Temperature stable to more than 260o C (500oF).

• May be used in combination with other additives, particularly lost circulation materials.

Packing and Storage

GRAPHITE is packaged in a 25 kg (55.1 lb), multi-wall paper sack.

Store at moderate temperatures in a well-ventilated and dry area

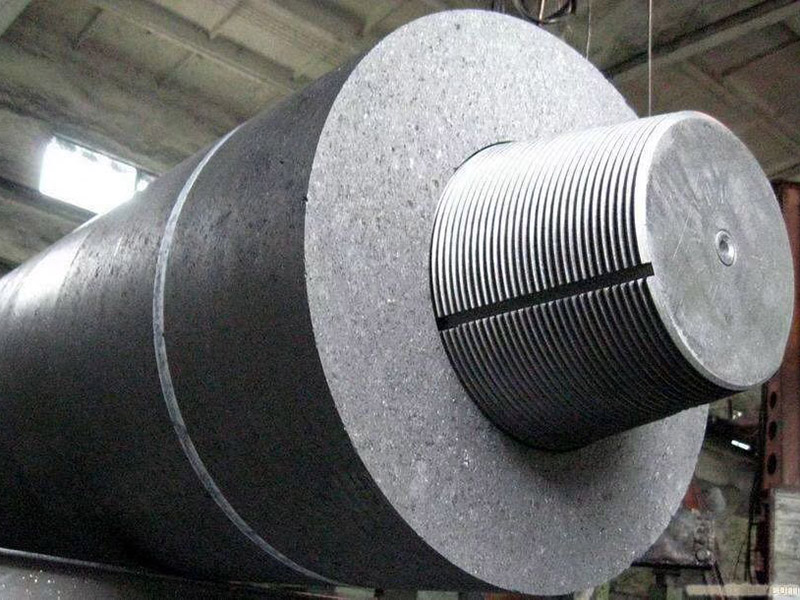

Product detail pictures:

Related Product Guide:

We've one of innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for High Quality Synthetic Graphite Powder - Bulletin Graphite Resillient Graphite – Sungraf , The product will supply to all over the world, such as: Mexico, Portland, Luxembourg, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the high quality products with lower price. We are looking forward to doing business with you!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.