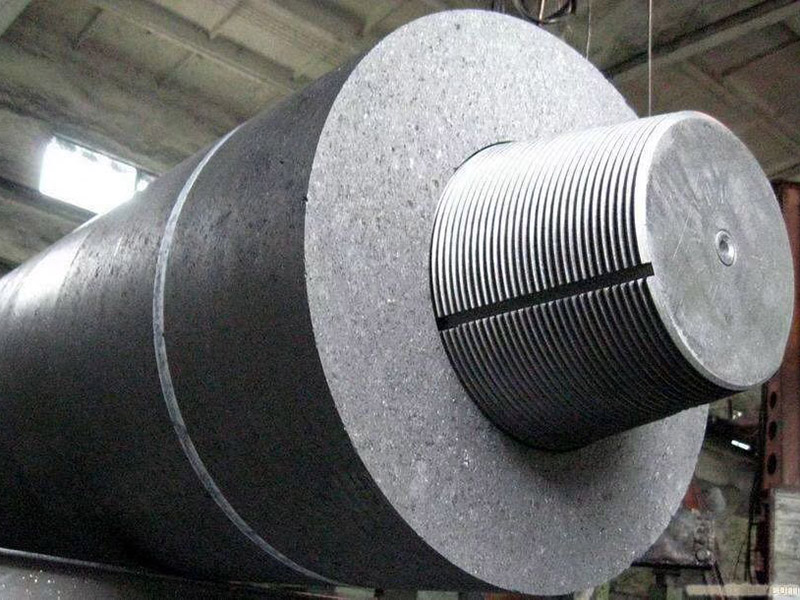

Manufacturer for Graphite Arc Electrode - UHP Grades Graphite Electrodes – Sungraf Detail:

Products Details

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage

-

01

An increasing proportion of global steel is made using electric arc furnaces -

02

The electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Typical properties of UHP graphite electrodes

|

Applicable Furmace Dia |

AC Furnace |

DC Furnace |

|||

|

300-400mm |

450-500mm |

550-600mm |

650-700mm |

||

|

Bulk Density |

g/cm³ |

1.65~1.76 |

1.64~1.75 |

1.64~1.75 |

1.64~1.75 |

|

Specific Resistance |

μΩM |

4.2~6.0 |

4.2~6.0 |

4.2~6.0 |

4.2~5.5 |

|

Elastic Modulus |

Gpa |

7~14 |

7~14 |

7~14 |

7~14 |

|

kgf/mm² |

700~1,400 |

700~1,400 |

700~1,400 |

700~1,400 |

|

|

Flexural Strength |

MPa |

10.5~15 |

10~15 |

10~15 |

10~15 |

|

kgf/cm² |

105~150 |

100〜150 |

100-150 |

100~150 |

|

|

N/cm² |

1,050~1,500 |

1,000~1,500 |

1,000~1,500 |

1,000~1,500 |

|

|

Coefficient Of Thermal |

X10~-6/℃ |

1.0~1.5 |

1.0~1.5 |

1.0~1.5 |

1.0~1.4 |

|

Real Density |

g/cm³ |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

|

Porosity |

% |

20~26 |

20~27 |

20~27 |

20~27 |

|

Ash Content |

% |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

Typical properties of nipples

| Specifications |

≤φ400 |

φ450-500 |

φ550 |

φ600-700 |

| Specific Resistance (μΩM ) |

≤4.0 |

≤3.8 |

≤3.6 |

≤3.6 |

| Flexural Strength (MPa) |

18-24 |

17-25 |

20-28 |

20-28 |

| astic Modulus (GPa) |

≤18 |

≤18 |

≤18 |

≤18 |

| Bulk Density (g/cm³) |

1.76-1.84 |

1.78-1.84 |

1.79-1.86 |

1.79-1.86 |

| Coefficient Of Thermal Expansion (106/℃) |

0.9-1.3 |

0.9-1.2 |

0.9-1.1 |

0.9-1.1 |

| Ash Content (%) |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Current carrying capacity for UHP graphite electrodes

| Current Capacity Of UHP Graphite Electrodes | |||||

| Specifications | Current Capacity(A) | Current Density(A/cm²) | |||

| (inch) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |

Product detail pictures:

Related Product Guide:

Sticking to the perception of Creating products of front end of range and earning mates with people today from all over the world, we constantly put the desire of consumers in the first place for Manufacturer for Graphite Arc Electrode - UHP Grades Graphite Electrodes – Sungraf , The product will supply to all over the world, such as: belarus, Barbados, Hyderabad, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!