Faahfaahinta Alaabta

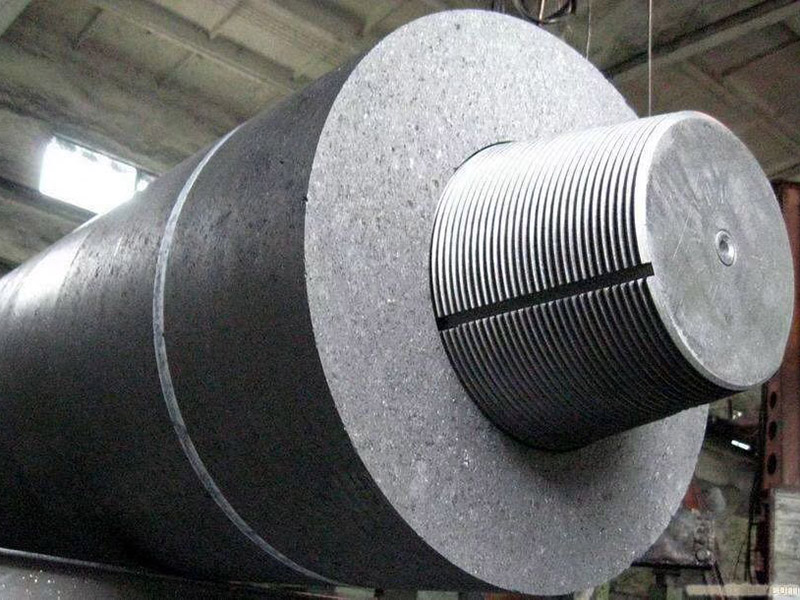

Electrodes-yadu waxay wataan koronto kuleysa foornooyinka korantada, foornooyinka birta ee ugu badan.Waxa laga sameeyaa kookaha batroolka ka dib marka lagu qaso garoonka batroolka, la soo saaro oo la qaabeeyo, ka dibna lagu dubay si ay u miiraan, ka dibna graphitized iyada oo lagu kululeynayo heerkulka (3000 ° C) taas oo u beddeleysa kaarboon graphite.Waxay ku kala duwanaan karaan cabbir ahaan ilaa 11 fuudh. dheer iyo 30 inji dhexroor ah.

Isticmaalka

- 01 Qayb sii kordheysa oo ah birta caalamiga ah ayaa lagu sameeyaa iyadoo la isticmaalayo foornooyin koronto ah

- 02 Foornada arc koronto lafteedu waxay sii fiicnaanaysaa oo waxay samaynaysaa bir badan halkii tan oo elektrode ah

Astaamaha caadiga ah ee electrodes graphite UHP

| Foornada lagu dabaqi karo Dia | Foornada AC | Foornada DC | |||

| 300-400mm | 450-500mm | 550-600mm | 650-700mm | ||

| Cufnaanta Bulk | g/cm³ | 1.65 ilaa 1.76 | 1.64 ilaa 1.75 | 1.64 ilaa 1.75 | 1.64 ilaa 1.75 |

| Iska caabin gaar ah | μΩM | 4.2 ilaa 6.0 | 4.2 ilaa 6.0 | 4.2 ilaa 6.0 | 4.2-5.5 |

| Qalabka Elastic | Gpa | 7 ~14 | 7 ~14 | 7 ~14 | 7 ~14 |

| kgf/mm² | 700 ilaa 1,400 | 700 ilaa 1,400 | 700 ilaa 1,400 | 700 ilaa 1,400 | |

| Xoog Jilicsan | MPa | 10.5 ilaa 15 | 10 ilaa 15 | 10 ilaa 15 | 10 ilaa 15 |

| kgf/cm² | 105 ilaa 150 | 100 - 150 | 100-150 | 100 ilaa 150 | |

| N/cm² | 1,050 ilaa 1,500 | 1,000 ilaa 1,500 | 1,000 ilaa 1,500 | 1,000 ilaa 1,500 | |

| Isku-dhafka Thermal | X10~-6/℃ | 1.0 ilaa 1.5 | 1.0 ilaa 1.5 | 1.0 ilaa 1.5 | 1.0~1.4 |

| Cufnaanta Dhabta ah | g/cm³ | 2.20-2.23 | 2.20-2.23 | 2.20-2.23 | 2.20-2.23 |

| Porosity | % | 20 ilaa 26 | 20-27 | 20-27 | 20-27 |

| Waxyaabaha Dambaska ah | % | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

Tilmaamaha caadiga ah ee ibta naasaha

| Tilmaamaha | ≤φ400 | φ450-500 | φ550 | φ600-700 |

| Iska caabin gaar ah (μΩM) | ≤4.0 | ≤3.8 | ≤3.6 | ≤3.6 |

| Xoog Jilicsan (MPa) | 18-24 | 17-25 | 20-28 | 20-28 |

| astic Modulus (GPa) | ≤18 | ≤18 | ≤18 | ≤18 |

| Cufnaanta Weyn (g/cm³) | 1.76-1.84 | 1.78-1.84 | 1.79-1.86 | 1.79-1.86 |

| Isku-dhafka Balaadhinta kulaylka (106/℃) | 0.9-1.3 | 0.9-1.2 | 0.9-1.1 | 0.9-1.1 |

| Waxyaabaha Dambaska ah (%) | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

Awood qaadista hadda ee UHP graphite electrodes

| Awooda hadda ee UHP Graphite Electrodes | |||||

| Tilmaamaha | Awooda hadda (A) | Cufnaanta Hadda (A/cm²) | |||

| (inji) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |